A stone engraving machine is functional when engraving designs and images on stones and other materials. Monuments, grave markers, and other stone-based artwork commonly benefit from their use. Its three primary components are the controller, the software, and the laser. Slate, marble, granite, and limestone are just a few stones that an individual can engrave with a stone laser engraving machine. The machine removes a thin layer of stone’s surface material during the technique using a laser beam.

What You Should Learn About Stone Laser Engraving Equipment

Using stone laser engraving machines is an excellent method for personalizing your stone items. Find out more about the information you require before completing a purchase.

How a laser engraving machine for stone operates

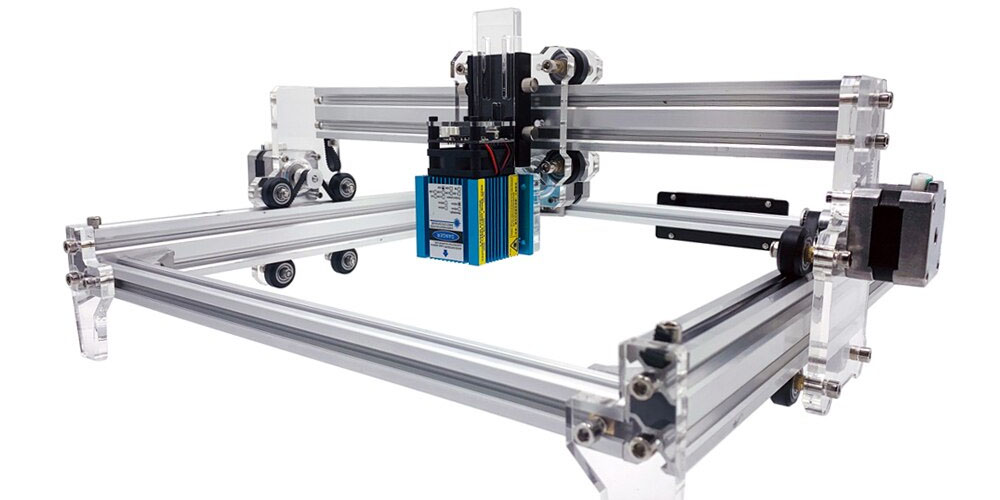

With the aid of a laser beam, this equipment engraves the stone. Then it moves in an X pattern to impress the same design throughout the entire stone’s surface. A computer controls the machine and can adjust the engraving’s depth and width. Rocks require a higher power level, whereas metals and trees require a lower one. The device directs an intense laser beam toward the stone’s surface before being converted into an electrical signal. The signal travels via an optical system before being concentrated by a lens to produce an intense laser beam. The strength of this beam determines how deep and wide the engraving will be on the stone’s surface.

Materials that a stone engraving machine can engrave

A Stone laser engraving machine can engrave numerous materials. Slate, marble, granite, and other kinds of stone can all benefit from it. It can also engrave on glass, metal, and wood. Different stone types have different characteristics and limitations. The kind of materials that a stone engraving machine can work with will depend on these characteristics. Others are more flexible and can handle both sorts, while specific engraving machines can only take soft stones. A stone engraving machine’s ability to etch different materials depends on several factors. The stone’s type and style, the item’s size and shape, the material’s hardness, and the operator’s level of experience are some of them.

The best stone engraving machine selection

There are a few things to consider while selecting the stone engraving machine that best meets your needs. If you utilize it for heavy-duty tasks, you will need a device that can handle the workload that can handle it. If you were using the machine for light-duty operations, any speed would be adequate, but if you were taking heavy materials, getting one with more excellent rates was crucial. Depending on the material you will be engraving, you will require a specific type of stone engraving machine.

Conclusion

The stone laser engraving machine is a modern solution to the demand for customized engraving. The machine’s main benefits are its accuracy and speed. Stone laser engravers can operate with many materials at once, producing high-quality results quickly and efficiently, which shortens production times and the amount of work needed from the artist or artisan who would otherwise have to create each item by hand. Because of this, it is the ideal option for small enterprises and amateurs who want to design customized gifts.