Although rapid tooling has been available for a while, it has only just been clear how beneficial adopting this technology may be. Rapid Tooling, which frequently utilizes 3D printing technology, may be utilized to make molds and dies that are needed in the manufacturing process. This post will discuss quick tooling, including what it is, how it operates, and how it may help your company.

What is Rapid Tooling?

Rapid tooling is a method of fabricating tools that dies quickly and economically. Rapid tooling is the process of making molds or dies in hours or days instead of weeks or months, as opposed to conventional machining processes which can take up to six months. This speed reduction allows for quicker cycle times, increased flexibility, and lowers costs. For more details you can visit prototype molding services.

Types of Rapid Tooling Processes

In this section, we’ll cover the different types of rapid tooling processes, and what they can be used for.

Direct Metal Laser Sintering (DMLS) is a process that uses lasers to melt the metal powder into 3D shapes. It’s most commonly used for creating metal parts with intricate geometries or complex overhangs (such as teeth).

Selective Laser Sintering (SLS) uses a laser to fuse together powdered material into solid objects layer by layer. This process is best for creating small-scale parts with complex geometries and surface details—and you can use almost any material, whether it’s plastic, metal, or ceramic!

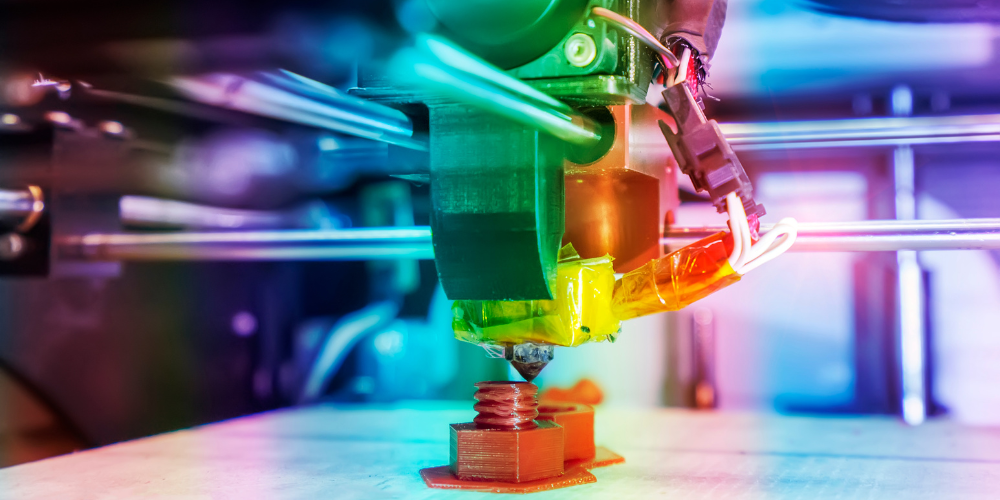

Fused Deposition Modeling (FDM) is an affordable way to create prototypes out of thermoplastic materials like ABS plastics or nylon-based filaments. It’s also increasingly popular in product development due to its ability to create multiple interlocking parts that can be assembled later on in manufacturing—but keep in mind that these parts won’t last forever!

Shorter lead-time.

With rapid tooling, it’s possible to produce a prototype within days, instead of the weeks or months it would take for conventional tooling. It can also be done in hours or even minutes, depending on your needs. With this kind of speed, you can get your product out into the market much sooner than before.

This means that you can test your product idea before committing to the expensive process of full-scale production. You may find that your product works just fine with rapid tooling, or it might need some slight modifications before going into full-scale production.

High-quality Mold.

One of the main advantages of rapid tooling is that it’s capable of producing high-quality molds. Rapid tooling is not cheap, but the investment is worth it when you take into account how precise, fast and efficient it can be. This process makes molds in two or three days rather than weeks or months. In addition to being fast, the process is also highly accurate and produces consistent results with each new product produced using this technique.

Rapid tooling offers several advantages over traditional methods such as CNC machining (Computer Numeric Control). If you’re looking for a low-cost way to produce prototypes for new products, then look no further than rapid tooling!

Suitable for small-batch products.

Rapid tooling is suitable for small-batch products.

Small-batch products are often produced in low volumes and made over a short period of time, making it difficult to justify the cost of conventional tooling. Rapid tooling can be used in these situations because it enables the production of prototype tools at a fraction of the cost of their metal counterpart.

Conclusion

Rapid Tooling is a great tool for any company to have in its toolbox. It has many advantages that make it more cost-effective and efficient than traditional methods of manufacturing, but it also requires careful planning to ensure success. With the right knowledge and preparation, you can be sure that using rapid tooling will pay off big time!